Tag: flight

2020: A Rocketry Year in Review

The rearview mirror

A little over one year ago, I came across a question on Quora (an internet forum) about whether it would be legal to build and launch your own rocket into orbit.

I’d always been interested in rockets and space, but I never seriously considered doing this or even realized it was possible, or legal. How realistic is this kind of project? Do you need anyone’s permission, i.e. the FAA? The US government?

One month and an uncountably high number of Google searches later, I was actively exploring the possibilities.

Near the end of 2019 (before we had any idea what kind of year 2020 would be), I set a few rocketry-related goals for myself. I was just realizing that anyone can build and launch real, working model rockets. And they could build and launch big ones, too – high power rockets. I decided to try it out, first building a few smaller low power rockets and sending them up with a small launch pad, and then building my first high power rocket. Somewhat unexpectedly, one of the bigger obstacles I ran into wasn’t the construction of the rockets, but finding a suitable launch site. But I found a few places and had some initial successes. I set some concrete goals going into the new year.

My 2020 goals included the following:

- build and successfully launch my first high power rocket;

- get my NAR HPR level 1 certification (H or I motor);

- get my level 2 certification (J, K, or L motor);

- build my first electronics bay, learn more about flight computers, and use dual deploy for parachutes;

- get my amateur (“ham”) radio license;

- renovate my backyard garden shed and build a practical workshop, primarily for rocket projects;

- get my level 3 certification (M, N, or O motor); and

- build a two-stage rocket.

Overall, things went pretty well. I didn’t achieve everything on the list, but I did accomplish many of these things and got some high power rocketry experience under my belt – basically everything except the L3 cert and the two stage rocket. And I did actually build my L3 rocket (three separate times!) but had two flight certification attempts that were not successful, so I came close but didn’t quite pull it off. In general, I did a lot of stuff I’d never done before, and learned a tremendous amount along the way.

In short, I had a blast!

The future plans

Turning to 2021, it’s a new year and time to set some new goals. The logical starting point is with the goals I didn’t quite get to finish in 2020. Was I too ambitious? Crazy? Did I just run out of time? Who knows?

Since I already rebuilt my L3 rocket for the third time and it’s ready to fly, my first goal is getting my L3 certification. This will let me fly M, N, and O motors (and there are some even bigger ones beyond that, but first things first). There are no additional certification levels, though, after L3.

Next, I intend to build a two stage rocket. It can be fairly simple and inexpensive – no need to start off with something overly complex right off the bat – but I want to get a solid understanding of staging, and specifically staging using electronics (multiple flight computers). There are a couple important “events” with a two stage rocket, but basically the first stage (booster) ignites on the ground and “boosts” it high into the air, and then the second stage (sustainer) ignites mid-air. The first stage also breaks off and falls back to the ground at this point, reducing total weight and drag so the sustainer can fly much higher on its own. I’ll have much more to say about this two stage project once I dive in.

After that, I’d like to start on a more ambitious two stage project – something made of fiberglass, minimum diameter, and more sophisticated. Ideally I might be able to build a two stage rocket using one M and one N motor that can hit 100,000 ft, but more likely it would be a high altitude rocket that goes a few tens of thousands of feet into the air. I’ll see what’s realistic as I get closer to this goal.

In the meantime, I’m also taking some more math and science classes in 2021. Right now I’m enrolled in a chemistry course as well as a geology course dedicated to dinosaurs. The latter is entirely just for fun and has nothing to do with rocketry, but it isn’t extremely time consuming or demanding either. Chemistry is much more intense, but it’s also much more critical to rocketry, especially if I want to eventually build my own solid fuel motors or get into liquid fuel or something down the road.

Here’s to 2021!

Video: High Power Rocketry NAR level 2 cert flight – slow motion

Video: L3 cert flight attempt #2

Going down in flames: how to self-destruct with rockets

The big day was finally here.

I finished building the L3 Fusion rocket in early September and was ready to launch – once the wildfire smoke cleared in the PNW – as soon as the opportunity arose. And in late October, I had my chance.

The plan

On a frigid Saturday morning, with my wife joining the small crowd gathered at the rocket launch out near Walla Walla, WA, I went through my pre-launch checklist and got the rocket ready for flight. It was mostly ready to go – the black powder charges were prepared and loaded inside the rocket, the M-1297 reloadable motor was already built, the wiring for all the electronics was nearly complete. All I needed to do was plug each flight computer into its respective battery, turn on the GoPro camera, and seal up the rocket with a few rivets. And, of course, install the motor. Easy enough.

I’ve described this rocket before but just to quickly recap, the L3 Fusion is a 5.5″ diameter, nearly 8 ft tall high power rocket specifically designed for level 3 certification. It’s available from SBR at fusionrocket.biz and I highly recommend it. The rocket is cardboard and therefore lightweight (only 11 lbs before adding the M motor, which itself weighs another 11 lbs), but it’s reinforced and double-tubed from top to bottom, and then coated with an epoxy – basically making the rocket incredibly strong despite the light weight. On an M-1297 motor, this thing should fly to 9,000 ft or higher.

The key word, of course, is “should.”

I was a bit nervous, but mostly hopeful and excited. The temperature that morning was brisk – around 30 degrees F – and it didn’t take long for my fingers to get cold and then start to feel numb. It’s particularly difficult when you’re trying to mess with very tiny wires and electronics – think eyeglasses screwdriver (which is literally what I was using to attach wires to flight computers).

But I had built this rocket entirely under the watchful eye of the man who designed it, with his recommendations. We even filmed the entire build as a tutorial for future generations, so this event might go down in history. I can’t say I built the rocket flawlessly, but I was pretty confident the flight would be successful.

As you have probably guessed by now, it was not.

The disaster

The countdown began: 5… 4… 3… 2… 1…

With a thunderous roar, the rocket shot off the pad and climbed into the sky with lightning speed. An M motor is a pretty powerful one, and so this was expected. What was not expected was just a few seconds into the flight, as we watched it ascend and disappear into the sky, was another loud boom. The smoke behind the rocket, which was otherwise basically a vertical line, suddenly changed as the rocket veered sharply from its trajectory.

It broke up and fell back to the ground in multiple pieces, and the certification attempt was a bust.

We mounted a search with half a dozen people scouring the hilly area where we saw the parts land, and we were able to find and recover everything except for the rocket’s three fins. The fins were completely torn off, but a lot of the rest of the rocket was largely undamaged. We even found the electronics, despite the fact that the e-bay fell separately from the rest of the rocket and it’s quite small and difficult to spot in small bushes and tall grasses on a hill.

The aftermath

You can learn a lot from studying a rocket failure, just by seeing what happened to the airframe. You can sometimes learn even more if you recover the electronics and download the flight data (assuming they’re still working properly), and/or from an onboard camera like a GoPro.

In this case, it seemed obvious that the fins experienced fin flutter, which is a phenomenon where the forces acting on the fins are much higher than they should be under normal flight conditions, and the extreme vibrations can either change the rocket’s trajectory or even destroy the fins.

Leaving aside complicated discussions of aerodynamics, fins are really important to a rocket. The rocket itself is streamlined and has a motor at the bottom which accelerates the rocket upwards (vertically), but anytime the rocket deviates from that vertical path, the fins stabilize it. The air pushing against the broad fins with large surface area pushes the bottom of the rocket back into place. It’s an ingenious system that self-corrects without the need for a sophisticated computerized guidance system. (Very sophisticated and large rockets tend not to have fins precisely because they do have such computerized guidance systems.)

Without fins, the rocket has no stability. In this case, the moment one or more fins were damaged due to flutter, the rocket careened significantly off its straight trajectory. Since it was still traveling at very high speeds just a few seconds into the flight, the forces acting on the rocket were tremendous and it was almost instantly destroyed.

As you can see in the picture above, the entire bottom of the booster section of the airframe was destroyed and all three fins were torn off. Some of the rest of the airframe was damaged, despite the fact that it was double tubed and reinforced with some serious epoxy. And the drogue (smaller) parachute disappeared into oblivion.

But much of the rocket was surprisingly undamaged. The larger parachute never even unraveled and was completely fine, along with both white shock cords connecting everything together. The nose cone and electronics were in great condition as well. Unfortunately both flight computers had their batteries ripped out during this event so they lost power and stopped recording data after the first few seconds, but both are in perfect working order and only needed new batteries, an easy fix.

The conclusion

It also seems clear that the cause of the fin issue was my own flawed construction technique. Typically, with previous rockets, I’ve built the fin can (i.e. the section of the rocket consisting of the motor mount tube and the fins) outside of the larger diameter rocket airframe, and then inserted the fin can into the airframe. This allowed me to use plenty of epoxy attaching the fins to the motor mount tube at the root edge of the fin, and to build up thick epoxy fillets.

In this case, however, I inserted the motor mount tube into the airframe first, and then attached the fins “through the wall” of the airframe tube. I likely didn’t use nearly enough epoxy on the root edge of the fins when inserting them – and because of this, at least one was yanked off during flight when it experienced flutter.

The reboot

I knew what I had to do. Rebuild the entire rocket (salvaging a few parts from the original if possible, like the parachute and shock cords) and this time, build the fin can outside the airframe and use plenty of epoxy on the fins. Make sure those fins are securely attached and incredibly strong.

Which is exactly what I did, for my level 3 certification attempt #2, just three weeks later.

How did that attempt go, you ask? Well, let me go put on some coffee and I’ll tell you all about it..

Video: L3 cert flight attempt #1

Going viral

I’ve periodically uploaded videos of some of my rocket launches during the past year (with more to come soon, of course). Generally, my YouTube videos don’t get a ton of views. Most of them have maybe 50 or 60 views; some of the more interesting ones have about 600-700. But one video seems to have really taken off – no pun intended.

What’s fascinating to me about this is: why? This is just a twelve second video clip of a rocket launch. It’s the Darkstar Extreme rocket that I built earlier this year, and this particular flight is on a K-535 motor, a common and standard workhorse motor. This video is not very different from several others that I’ve uploaded recently. Yet suddenly and without warning, the views started to dramatically increase: as of when I’m writing this, it’s topped 94,000 views.

As a nice side effect, it’s caused my YouTube channel to gain a bunch of new subscribers. Some sizeable fraction of people who casually see this clip want to subscribe – my total number of subscribers has risen from about 30 to over 170 in the past week or so. This is awesome, from my perspective.

I’m just not sure what accounts for this sudden interest. YouTube provides some analytics and it looks like most traffic (82 percent) is coming from YouTube Shorts, which is something new YouTube rolled out: a vertical video format that’s basically meant to compete with TikTok.

Another 13 percent of viewers are finding this through their suggested videos. Very few people are finding the video by using specific search terms (e.g. rocket launch).

But it’s still mysterious: why this particular video when I have several similar ones? Why now?

If anyone has any suggested explanations, I’d definitely be interested, since I’m still relatively new to this and figuring out how it all works!

Video: SBR 5.5″ L3 Fusion High Power Rocket, Part 2

Video: SBR 5.5″ L3 Fusion High Power Rocket, Part 1

Rocket flight data

Just to follow up on my last post, I wanted to provide some additional information and the actual flight data, and briefly explain what this all means, especially for all those folks reading this who are not familiar with anything related to rockets or flight computers. And for anyone who has significant experience flying rockets, you may find the below information interesting as well, without any explanation!

As a starting point: a flight computer is basically a very small circuit board that you put inside your rocket, and it has a bunch of neat built-in gadgets to measure exactly how high the rocket went, and how fast, and what interesting events happened when. I’ll explain more below.

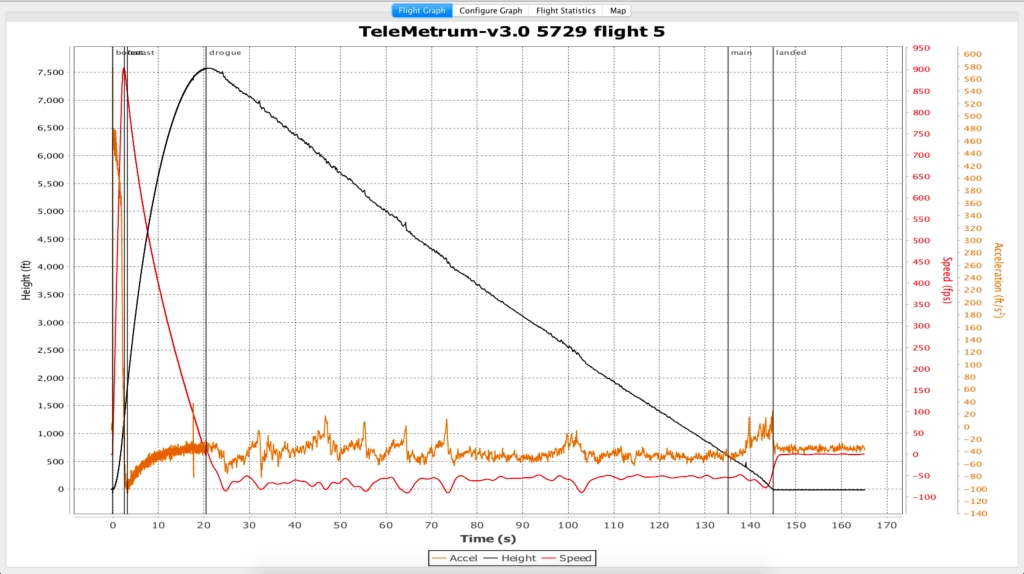

This is the relevant flight data for the flight I mentioned in my last post, which went over one mile high:

So what does all of this mean?

First of all, it means that the rocket flew to a maximum height of about 7,579 ft – you can see this in “maximum height.” This measurement is made by a barometer taking air pressure readings in the flight computer, starting at ground level on the launch pad, and then many times while it’s in flight. There’s also a GPS chip on this flight computer and you can see it also independently measures the height using GPS, but I’m just going to assume the lower value is more likely correct.

The flight computer also records the maximum speed, which in this case was 904 feet per second (fps), which is equivalent to Mach 0.8, or a little bit slower than the speed of sound.

The total flight time was 145 seconds (just over two minutes), and there’s a further breakdown of how long the rocket spent going up and then coming back down.

The graph is even more intuitive:

This reflects the same data described above. The black line is the easiest to understand: it represents the rocket’s actual height over time. As is generally the case (unless you experience a catastrophic failure), the rocket zooms off the launch pad extremely rapidly and hits a maximum height early (here, just over 7,500 ft, as you can see from the black units to the left side), and then after parachutes deploy, it descends more slowly.

The red line is speed (extremely high at first and then plummets quickly), and the orange or gold line is acceleration. Both of these units are off to the right side of the graph.

It’s definitely fun to build and fly a rocket, but with modern flight computers and the ability to record all kinds of really precise data, you can really geek out on this stuff. How high can I fly? How fast can my rocket go? Is it descending at the right speed, or do I need a bigger (or smaller) parachute next time? This can really help refine your building and flying skills through a trial and error process, because you have access to reliable data. And needless to say, this can also help you find your rocket if you lose it because it lands really far away out of sight. In that situation, you’ll find the GPS coordinates onboard to be incredibly useful!